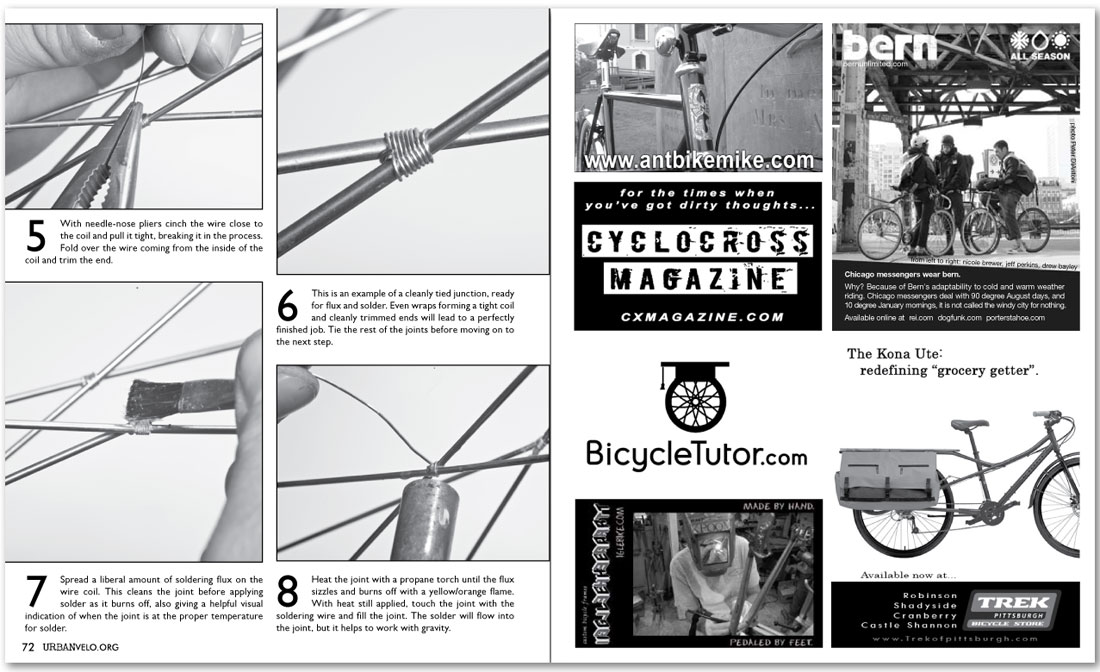

5 With needle-nose pliers cinch the wire close to the coil and pull it tight, breaking it in the process. Fold over the wire coming from the inside of the coil and trim the end.

6 This is an example of a cleanly tied junction, ready for flux and solder. Even wraps forming a tight coil and cleanly trimmed ends will lead to a perfectly finished job. Tie the rest of the joints before moving on to the next step.

7 Spread a liberal amount of soldering flux on the wire coil. This cleans the joint before applying solder as it burns off, also giving a helpful visual indication of when the joint is at the proper temperature for solder.

8 Heat the joint with a propane torch until the flux sizzles and burns off with a yellow/orange flame. With heat still applied, touch the joint with the soldering wire and fill the joint. The solder will flow into the joint, but it helps to work with gravity.