|

|||

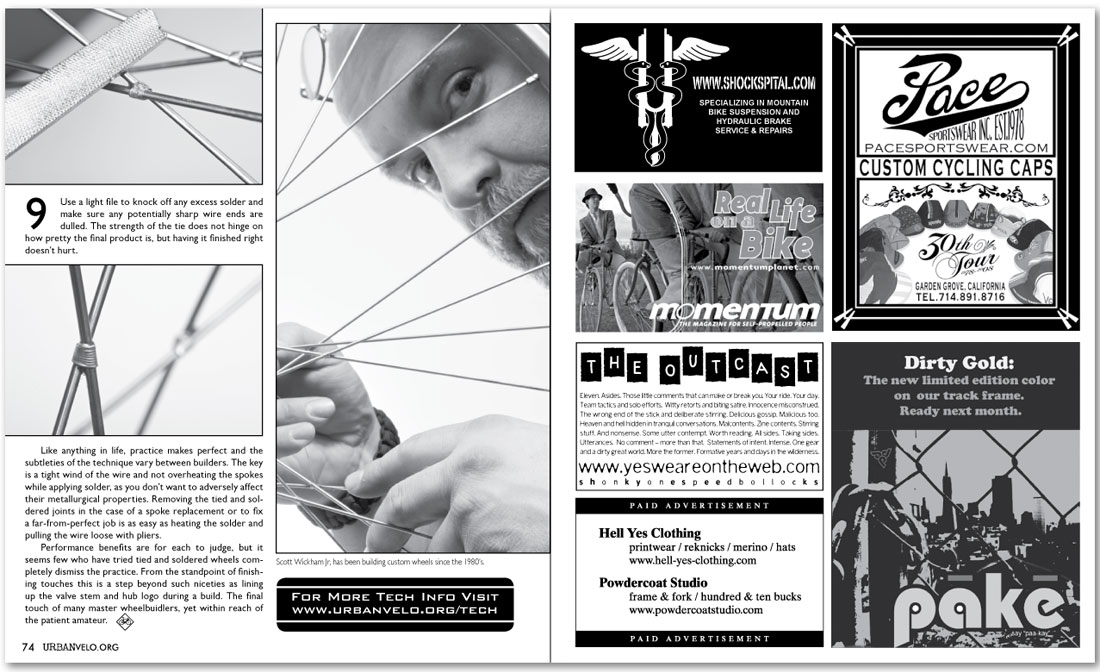

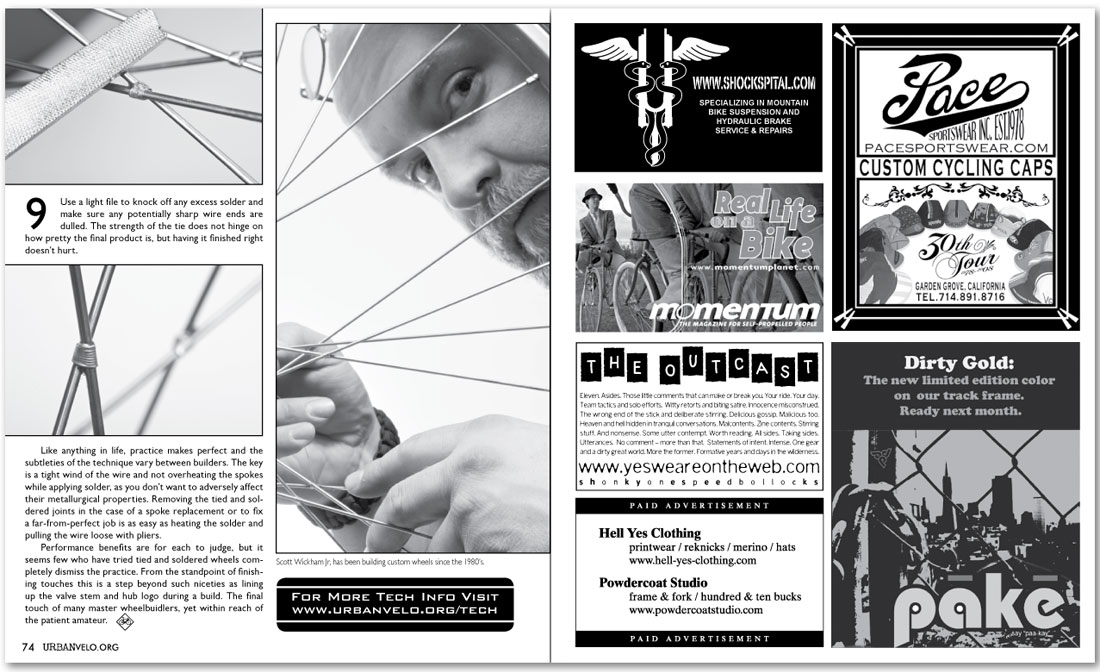

9 Use a light file to knock off any excess solder and make sure any potentially sharp wire ends are dulled. The strength of the tie does not hinge on how pretty the final product is, but having it finished right doesn’t hurt. Like anything in life, practice makes perfect and the subtleties of the technique vary between builders. The key is a tight wind of the wire and not overheating the spokes while applying solder, as you don’t want to adversely affect their metallurgical properties. Removing the tied and soldered joints in the case of a spoke replacement or to fix a far-from-perfect job is as easy as heating the solder and pulling the wire loose with pliers. Performance benefits are for each to judge, but it seems few who have tried tied and soldered wheels completely dismiss the practice. From the standpoint of finishing touches this is a step beyond such niceties as lining up the valve stem and hub logo during a build. The final touch of many master wheelbuidlers, yet within reach of the patient amateur. |

|

|

|