| Wheelbuilding 101... Continued

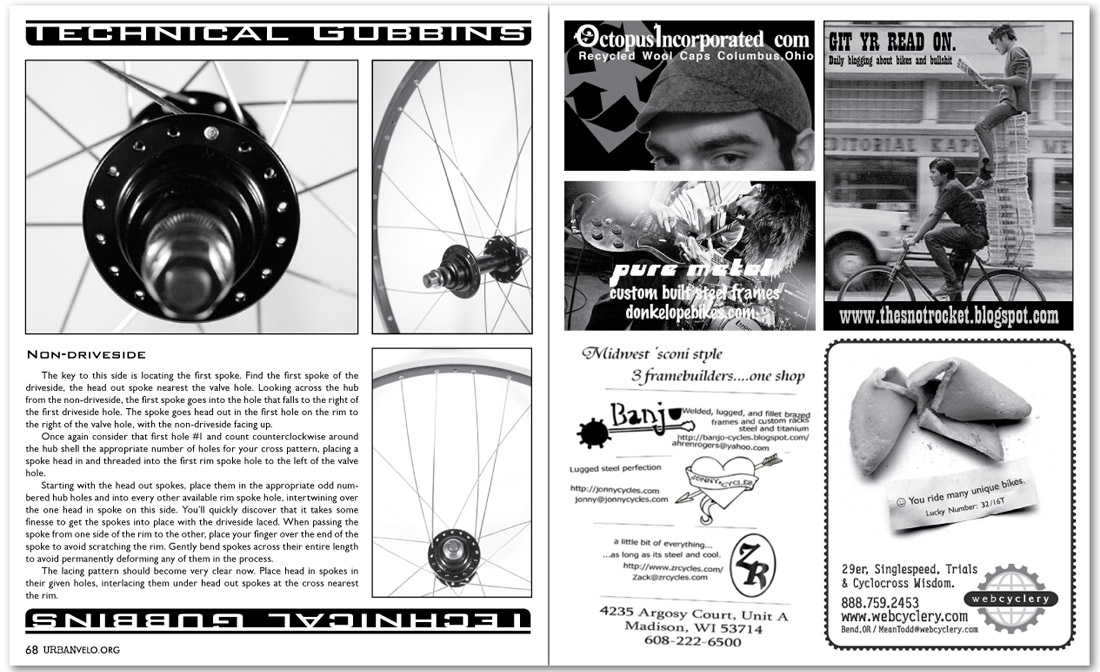

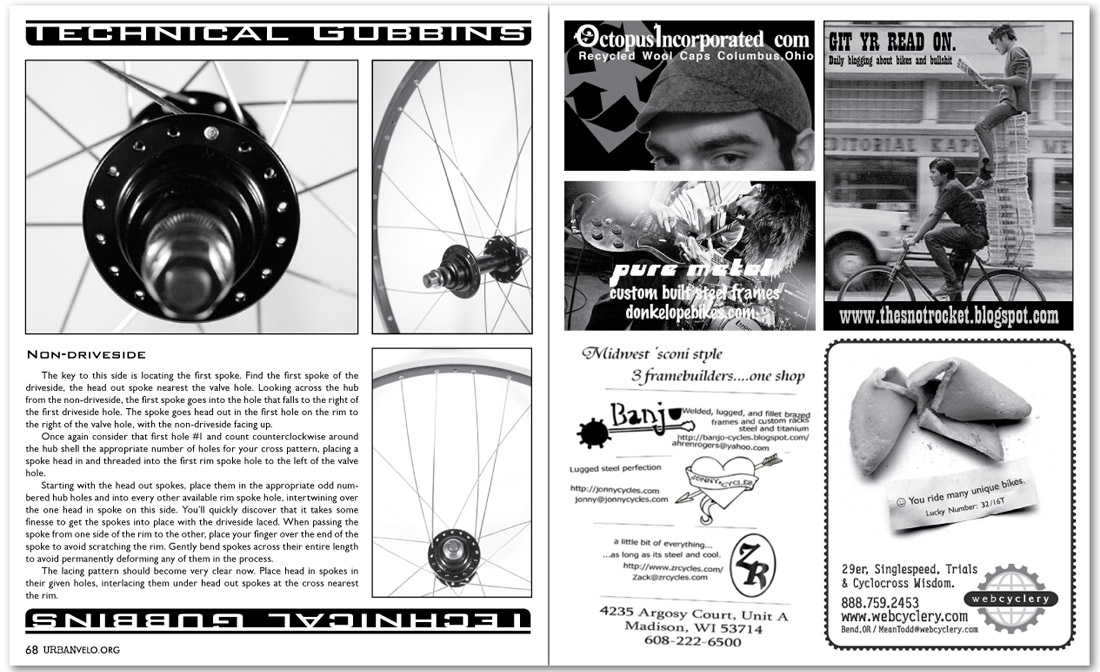

Non-driveside

The key to this side is locating the first spoke. Find the first spoke of the driveside, the head out spoke nearest the valve hole. Looking across the hub from the non-driveside, the first spoke goes into the hole that falls to the right of the first driveside hole. The spoke goes head out in the first hole on the rim to the right of the valve hole, with the non-driveside facing up.

Once again consider that first hole #1 and count counterclockwise around the hub shell the appropriate number of holes for your cross pattern, placing a spoke head in and threaded into the first rim spoke hole to the left of the valve hole.

Starting with the head out spokes, place them in the appropriate odd numbered hub holes and into every other available rim spoke hole, intertwining over the one head in spoke on this side. You’ll quickly discover that it takes some finesse to get the spokes into place with the driveside laced. When passing the spoke from one side of the rim to the other, place your finger over the end of the spoke to avoid scratching the rim. Gently bend spokes across their entire length to avoid permanently deforming any of them in the process.

The lacing pattern should become very clear now. Place head in spokes in their given holes, interlacing them under head out spokes at the cross nearest the rim.

(continued) |

|

|

|

|