|

||||

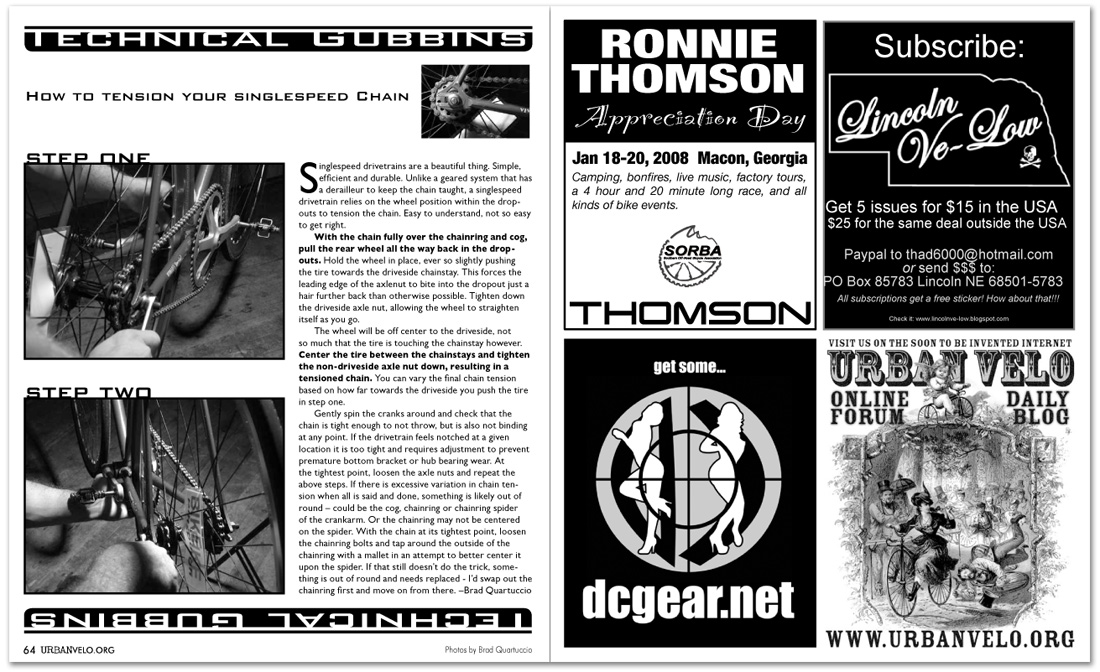

Technical GubbinsHow to Tension Your Singlespeed ChainSinglespeed drivetrains are a beautiful thing. Simple, efficient and durable. Unlike a geared system that has a derailleur to keep the chain taught, a singlespeed drivetrain relies on the wheel position within the dropouts to tension the chain. Easy to understand, not so easy to get right. With the chain fully over the chainring and cog, pull the rear wheel all the way back in the dropouts. Hold the wheel in place, ever so slightly pushing the tire towards the driveside chainstay. This forces the leading edge of the axlenut to bite into the dropout just a hair further back than otherwise possible. Tighten down the driveside axle nut, allowing the wheel to straighten itself as you go. The wheel will be off center to the driveside, not so much that the tire is touching the chainstay however. Center the tire between the chainstays and tighten the non-driveside axle nut down, resulting in a tensioned chain. You can vary the final chain tension based on how far towards the driveside you push the tire in step one. Gently spin the cranks around and check that the chain is tight enough to not throw, but is also not binding at any point. If the drivetrain feels notched at a given location it is too tight and requires adjustment to prevent premature bottom bracket or hub bearing wear. At the tightest point, loosen the axle nuts and repeat the above steps. If there is excessive variation in chain tension when all is said and done, something is likely out of round – could be the cog, chainring or chainring spider of the crankarm. Or the chainring may not be centered on the spider. With the chain at its tightest point, loosen the chainring bolts and tap around the outside of the chainring with a mallet in an attempt to better center it upon the spider. If that still doesn’t do the trick, something is out of round and needs replaced - I’d swap out the chainring first and move on from there. –Brad Quartuccio |

|

|