|

|||

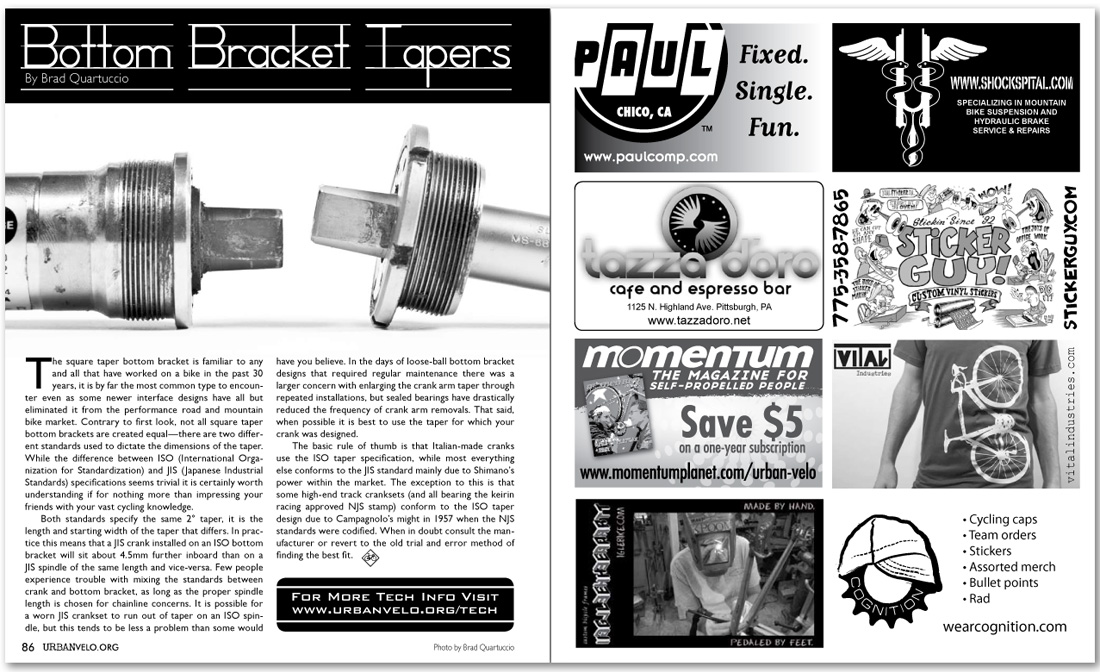

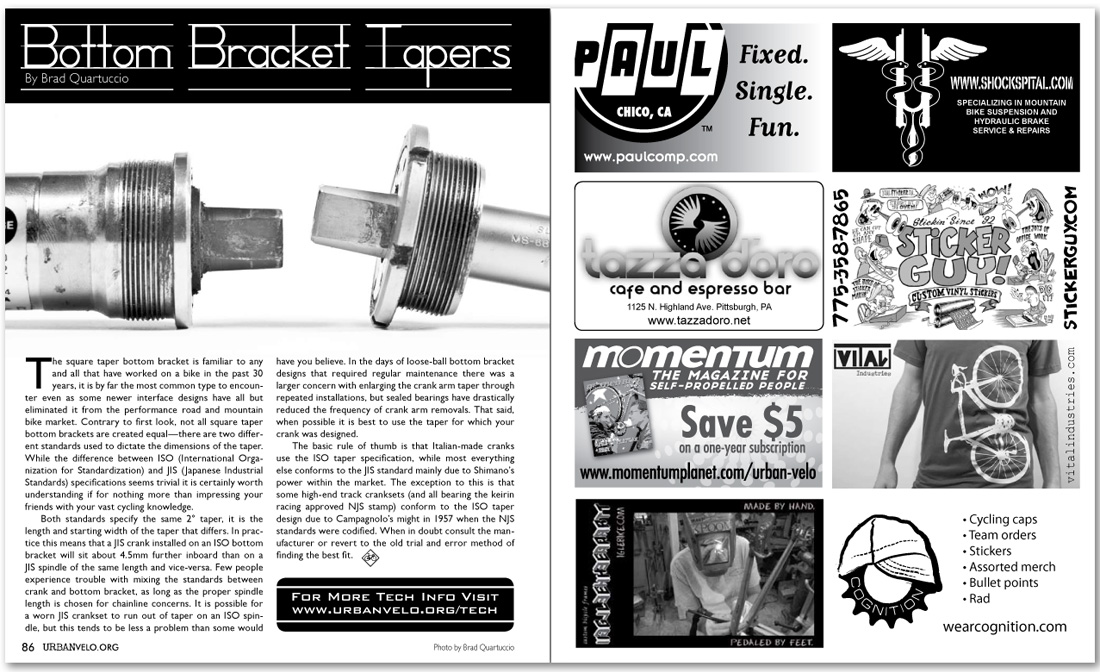

Bottom Bracket TapersBy Brad Quartuccio The square taper bottom bracket is familiar to any and all that have worked on a bike in the past 30 years, it is by far the most common type to encounter even as some newer interface designs have all but eliminated it from the performance road and mountain bike market. Contrary to first look, not all square taper bottom brackets are created equal—there are two different standards used to dictate the dimensions of the taper. While the difference between ISO (International Organization for Standardization) and JIS (Japanese Industrial Standards) specifications seems trivial it is certainly worth understanding if for nothing more than impressing your friends with your vast cycling knowledge. Both standards specify the same 2° taper, it is the length and starting width of the taper that differs. In practice this means that a JIS crank installed on an ISO bottom bracket will sit about 4.5mm further inboard than on a JIS spindle of the same length and vice-versa. Few people experience trouble with mixing the standards between crank and bottom bracket, as long as the proper spindle length is chosen for chainline concerns. It is possible for a worn JIS crankset to run out of taper on an ISO spindle, but this tends to be less a problem than some would have you believe. In the days of loose-ball bottom bracket designs that required regular maintenance there was a larger concern with enlarging the crank arm taper through repeated installations, but sealed bearings have drastically reduced the frequency of crank arm removals. That said, when possible it is best to use the taper for which your crank was designed. The basic rule of thumb is that Italian-made cranks use the ISO taper specification, while most everything else conforms to the JIS standard mainly due to Shimano’s power within the market. The exception to this is that some high-end track cranksets (and all bearing the keirin racing approved NJS stamp) conform to the ISO taper design due to Campagnolo’s might in 1957 when the NJS standards were codified. When in doubt consult the manufacturer or revert to the old trial and error method of finding the best fit.

|

|

|